VERICUT Users' Forum

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2012-11-01 01:33:03

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Performance pressets

Hi,

I think one helpful resource in future versions could be "performance pressets" so the user could go in a simple location and drag a slider to set the software performance, and Vericut would tune the entire project for that mode...

For example: If the user drags the slider to "Faster performance" then Vericut would increase the cut tolerance, set OpenGL quality to coarse mode, perhaps hide tool holders and things that impact on performace... this way the user could simulate a program faster when the goal is just to see the whole... after going through this he could drag the slider to "Normal" or "Quality mode" and Vericut would reduce the tolerances and activate the extra functionality...

The software could allow the user to create his own pressets and select the values / options that are enabled/disable in that given presset...

That is, a entire set of things that affects the software performace, as axis limits, tolerances, display quality, collision detection, etc... could be enabled/disable/work with pre-defined values that would allow the user to have performance when he needs it and quality when he needs it... it's easy to forget something when you have a bunch of things to change... presset modes would be a convenient and quick way to tune the entire software to the most suitable condition for a given objective.

Mastercam did this with their arc filtering wizard that help the user to use pre-defined modes for toolpath filtering... I think something like that in Vericut could simplify the usage and enhance the usability substantially...

What do you think?

Daniel Santos

Offline

#2 2012-11-13 18:25:42

- vhubbard

- Beta User

- From: Dallas, TX

- Registered: 2004-11-11

- Posts: 222

- Website

Re: Performance pressets

X2 on this one.....again.

We have turned in many requests to handle this problem. Setting up Vericut for speed vs. detail is a run around the interface. We need a sllider, mapkeys, co-location of commands, something.

Offline

#3 2012-11-14 12:52:04

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

Setting up Vericut for speed vs. detail is a run around the interface.

This is pretty much what it is. A long run...

Daniel Santos

Offline

#4 2013-03-02 04:28:57

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

X2 on this one too...

CGTech have here a good opportunity to make something really helpful in the next builds... it's very frustrating and time consuming to turn the software upside down everytime you want to change the simulation speed/quality. :cry:

These pressets are more a GUI enhancement and not a new material removal algorithm... so I presume they are easier to implement than other complex things... ![]()

If you also struggle with this, just post something like "+1 on this one" so CGTech can consider this more seriously... :wink:

Daniel Santos

Offline

#5 2013-03-07 09:55:08

- paehv

- Senior Member

- From: Eindhoven, Netherlands

- Registered: 2005-01-17

- Posts: 167

- Website

Re: Performance pressets

This can be improved, however the easiest and most effective setting (cutting tolerance under File > Properties) is just a few clicks away.

Patrick Delisse

KMWE Aerospace - https://www.kmwe.com

(Vericut V9.5, Siemens NX2206, Campost)

Offline

#6 2013-03-13 15:40:17

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

Hi Patrick,

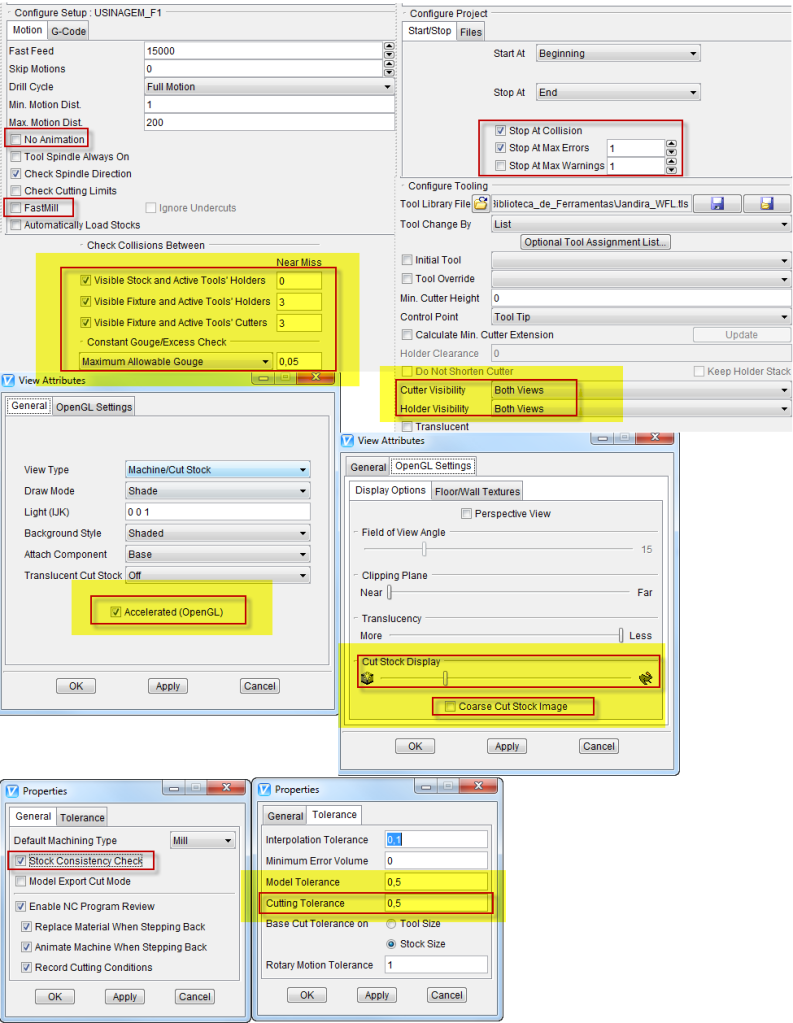

I agree with you that cutting tolerance is the major factor.. but all these ones below impact in the performace too, specially the ones in yellow... so IMHO, yes, it's a long run to mess with all settings that can affect performace/quality.

If we had performace pressets (The user could create up to four (or as many as he wants)) we could create combinations of the parameters below for a given need... if the guy just want to go trough the entire program to have an overview of errors, he could turn off certaing things in favor of performance... click on a presset icon and VERICUT is entirely set with those options... then he wants to do a finer check... click on the other presset icon (or in a combo list) and here you go...

Of course certain parameters could not be changed when going from one presset to another: cut tolerance, for example, is one of them... VERICUT could show a message box informing that and that's it...

Daniel Santos

Offline

#7 2013-03-13 20:46:37

- vhubbard

- Beta User

- From: Dallas, TX

- Registered: 2004-11-11

- Posts: 222

- Website

Re: Performance pressets

Good list, just a few additions.

With large parts with NC Program Review enabled will make HUGE files in the windows temp directory, slowing down the process as they are written to. Large is more than 1 megabyte G&M code.

Min and Max motion distance are important also. They are the Min/Max settings of the "Speed" slider. Going from a .06"/1.5mm drill to a 2"/50mm mill may require these to be changed if you want to see the drill.

Machine collision checking on/off. Once you know the program clears, successive runs usually have this off.

I have turned in ERs for many of these that don't have their own Menu-bar ICON to have an ICON, so we could at least group them close in the interface as we desire.

Offline

#8 2013-03-14 00:24:35

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

V,

I liked your idea!!! :wink:

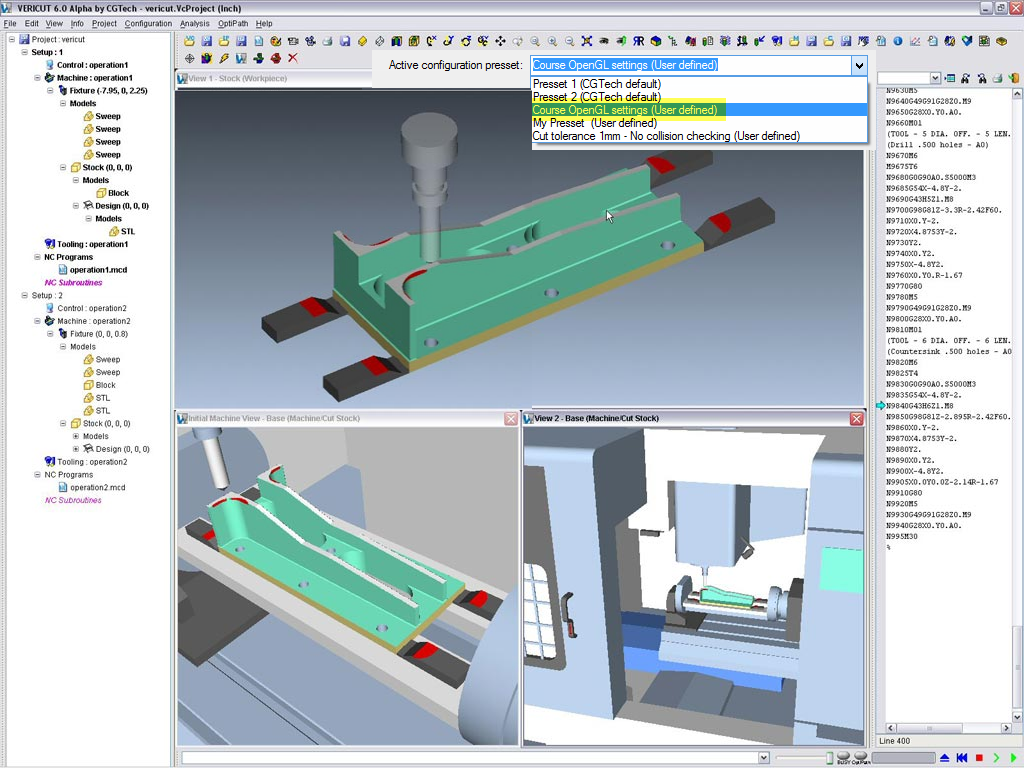

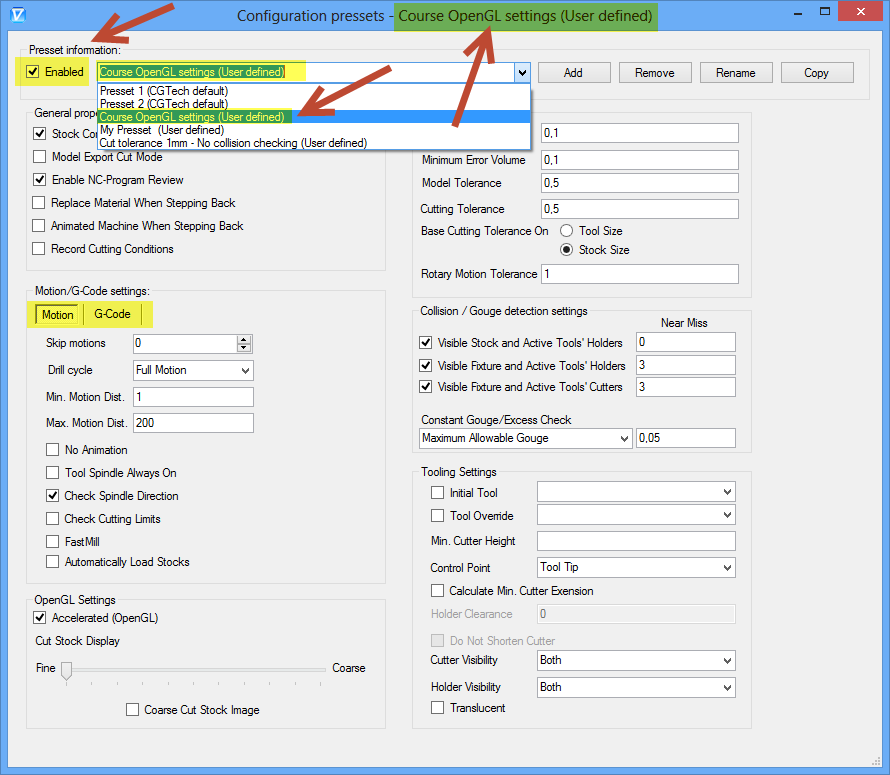

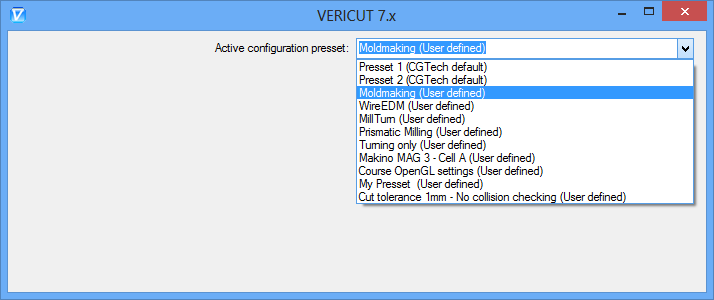

Complementing it, I prepared this conceptual UI to share what I have in mind... :idea:

If more people agree with the guys that replied to this post, please contact CGTech and ask them to increase the priority of this ER so that we all can benefit from a better workflow while using the software...

I think like many people we have a very diversified product line and it´s important to have the right settings for a given job... pressets can also help users to apply the best practices for specific scenarios without having to know it all by heart... or even worse: get different performance results because they left something checked/unchecked around the UI and forgot it... then they have to visit every dialog to find the root cause...

Some more :idea: for pressets:

Daniel Santos

Offline

#9 2013-03-15 15:32:04

- GavinP

- VERICUT Specialist

- From: UK

- Registered: 2004-10-14

- Posts: 58

- Website

Re: Performance pressets

Has anyone entered an ER for this Daniel?

Offline

#10 2013-03-15 15:56:35

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

Hi Gavin!

I asked our local office to do it... I presume yes - Plus the other requests v put in the past... I just want to make sure CGTech is looking into this seriously... this long run across the UI diminishes the beauty of VERICUT... :cry:

But if you want to bump someone in Irvine, we won't bother ![]()

Daniel Santos

Offline

#11 2013-03-22 18:57:59

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

Here is the SCR:

SCR #10096

Let's hope for the best! ![]()

Daniel Santos

Offline

#12 2014-03-28 09:40:27

- Tony

- Moderator

- From: Crewe, England

- Registered: 2007-02-20

- Posts: 182

- Website

Re: Performance pressets

I updated the dead hyperlink for this scr as well

Tony

Offline

#13 2015-02-07 00:21:18

- Vericut_McAtee

- Senior Member

- From: Fryeburg, Me.

- Registered: 2011-07-17

- Posts: 90

Re: Performance pressets

"+1 on this one"

Offline

#14 2016-03-04 22:16:21

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Performance pressets

Bump.

Daniel Santos

Offline

Pages: 1