VERICUT Users' Forum

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2011-09-20 13:38:04

- dirtydan_uk1

- Member

- From: Gateshead

- Registered: 2006-04-11

- Posts: 10

Cut Stock Tolerance.

Been using Vcut for a few yeears now but still haven't used many of it's funcions.

While ,at the moment I have a little spare time, I am trying out various things.

I have started with the cut tolerance in the Properties/Tolerance tab.

What are th Pros and Cons of setting Base cut tolerance to Tool size or Stock size?

I cannot see any appreciable difference on the test pieces I have tried.

Dan Archer

Senior Production Engineer [Oldest ha ha]

http://www.express-engineering.com/

Offline

#2 2011-09-20 13:46:59

- MIKEFITZ

- Member

- From: Chicopee, MA

- Registered: 2009-06-18

- Posts: 104

Re: Cut Stock Tolerance.

For simpler parts, it probably won't matter...for more complex parts with a lot of small features I usually set my tolerance to the smallest tool, since that will ensure that it is a fine enough tolerance to handle the smallest features without alloting excessive amounts of memory to the calculations. It should not, however, have any bearing on the actual cut stock model...it's still cutting the same part after all. This will allow Vericut to process as quickly as possible.

On the flip side, if the tolerance is not fine enough, Vericut will not show errors for small things like, if in G02/G03, the programmed radii are not the same size the machine can alarm out but Vericut might not catch them if they are close enough to be within the tolerance.

Generally, I just leave the cut tolerance alone unless Vericut suggests a different value.

Are you just trying to see what else is available in Vericut, or is there something specific that you are trying to do?

Mike

Hoppe Tool

Offline

#3 2011-09-20 13:51:36

- dirtydan_uk1

- Member

- From: Gateshead

- Registered: 2006-04-11

- Posts: 10

Re: Cut Stock Tolerance.

It usually defaults to Tool Size but I was wanting to know if there are

any advantages in choosing the Stock Size option.

Dan Archer

Senior Production Engineer [Oldest ha ha]

http://www.express-engineering.com/

Offline

#4 2011-09-20 14:05:43

- MIKEFITZ

- Member

- From: Chicopee, MA

- Registered: 2009-06-18

- Posts: 104

Re: Cut Stock Tolerance.

So long as the tool size tolerance is fine enough for what you're doing, there aren't really any advantages that I'm aware of in using the Stock Tolerance...I have never had an issue with using the Tool Size Tolerance

Mike

Hoppe Tool

Offline

#5 2011-09-20 14:31:53

- dirtydan_uk1

- Member

- From: Gateshead

- Registered: 2006-04-11

- Posts: 10

Re: Cut Stock Tolerance.

Me neither. Just trying to get it running as slick as possible.

Thanks for your input. I'll move on to something else now.

Dan Archer

Senior Production Engineer [Oldest ha ha]

http://www.express-engineering.com/

Offline

#6 2011-09-20 14:35:02

- MIKEFITZ

- Member

- From: Chicopee, MA

- Registered: 2009-06-18

- Posts: 104

Re: Cut Stock Tolerance.

Any time

Mike

Hoppe Tool

Offline

#7 2012-04-30 03:47:15

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Cut Stock Tolerance.

Hi folks,

This subject is very complex and too little real life examples are available in the help documentation, so I'll try to be more accurate here in order to get an accurate answer from CGTech or any of you...

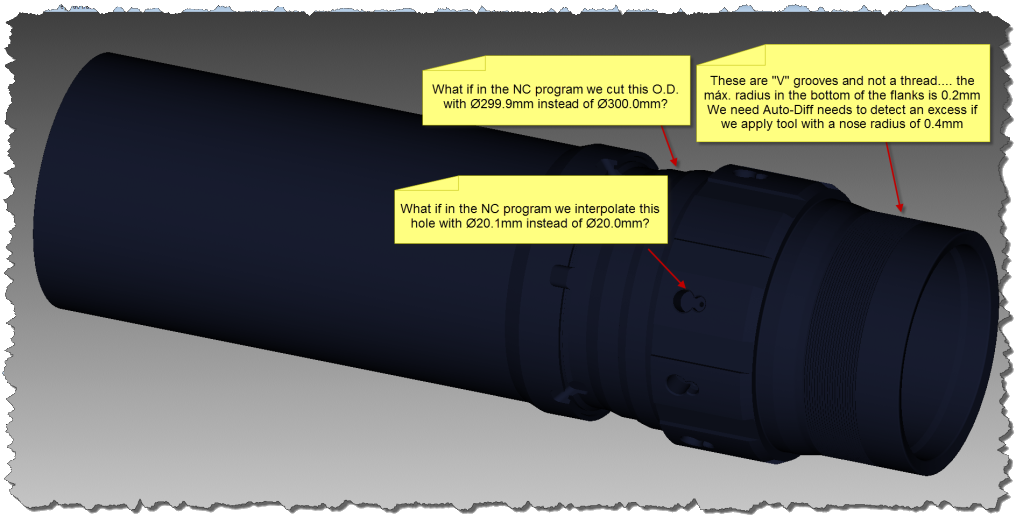

We're working with CGtech on a important mill turn project... and as the machine is complex, it's imperative to find the right accuracy to get good performance... however, Vericut is being deployed just because the components we produce are expensive and a small mistake is very costly... ![]()

We use to machine tubular parts with several 3+2 features around them, holes, threads, slots, grooves...

The average part size is 1200mm long, O.D. around 400mm, I.D around 300mm.

The O.D. has several diameters as well as the I.D. - We already had problems in the past that we made a mistake on the G-Code and an O.D. that should be machined with 300.0mm was cut with 299.9mm - Of course we didn't catch it... :cry: - That's why we're implementing Vericut now... we often use O.D. / I.D turnig tools with the nose radius having only 0.2mm

We also have some holes that are interpolated around the O.D using helical interpolation... let's say we have a 3+2 hole with a diameter of 20mm and we make the same mistake again on the program and we put coordinates on the G-Code that are supposed to cut the same diameter with 20.1mm...

With these part sizes, nose radius, hole dimensions and part diameters, what would be a good cut tolerance?

I'm willing to throw a big value in there like 1 mm and use stock size as the method, but I need to make sure we won't be bitten by a mistake Vericut didn't catch due to a course tolerance...

Any suggestions? Performance is very important and we don't want to waste memory when it's not necessary...

Thank you in advance,

Daniel

Daniel Santos

Offline

#8 2012-04-30 12:59:40

- MustaphaC

- VERICUT Specialist

- From: Le Mans, France

- Registered: 2004-10-14

- Posts: 130

- Website

Re: Cut Stock Tolerance.

Hello Daniel,

In general the best option to use is Cutting Tolerance based on Stock Size. That way you always use the same accuracy to all models you are cutting. Here are some hints to help you choose the best value:

- Try to keep the computer memory "inside the available RAM". Otherwise the simulation time will increase while "swapping" with hard disk

- Use a bigger Cutting Tolerance while "debugging" your NC program to remove all programming errors, collisions etc... (Note that NC Program Preview can already detect a lot of errors...)

- When all programming errors have been corrected, then you can use AUTO-DIFF with the "Compare By Region" with option "Improve Cut Stock Tolerance" and "Apply Regions Over Entire Stock" to make VERICUT to automatically move the region along the Cut Stock.

- In most cases a Cutting Tolerance between 0.5 to 1 for a mm project (0.02 to 0.04 for a inch project) based on Stock Size will give a good result during simulation to detect rapid motions and collisions, combined with AUTO-DIFF and "Compare By Region" with option "Improve Cut Stock Tolerance" to detect small gouges.

- And finally you can also read this topic <!-- l --><a class="postlink-local" href="http://www.cgtech.com/forum/viewtopic.php?f=2&t=1715">viewtopic.php?f=2&t=1715</a><!-- l --> which also has good information

Hope that helps!

Mustapha

Offline

#9 2012-04-30 14:27:41

- JaydenR

- Member

- Registered: 2012-04-30

- Posts: 1

Re: Cut Stock Tolerance.

Hello Daniel,

In general the best option to use is Cutting Tolerance based on Stock Size. That way you always use the same accuracy to all models you are cutting. Here are some hints to help you choose the best value:

- Try to keep the computer memory "inside the available RAM". Otherwise the simulation time will increase while "swapping" with hard disk

- Use a bigger Cutting Tolerance while "debugging" your NC program to remove all programming errors, collisions etc... (Note that NC Program Preview can already detect a lot of errors...)

- When all programming errors have been corrected, then you can use AUTO-DIFF with the "Compare By Region" with option "Improve Cut Stock Tolerance" and "Apply Regions Over Entire Stock" to make VERICUT to automatically move the region along the Cut Stock.

- In most cases a Cutting Tolerance between 0.5 to 1 for a mm project (0.02 to 0.04 for a inch project) based on Stock Size will give a good result during simulation to detect rapid motions and collisions, combined with AUTO-DIFF and "Compare By Region" with option "Improve Cut Stock Tolerance" to detect small gouges.

- And finally you can also read this topic <!-- l --><a class="postlink-local" href="http://www.cgtech.com/forum/viewtopic.php?f=2&t=1715">viewtopic.php?f=2&t=1715</a><!-- l --> which also has good informationHope that helps!

MustaphaC,

Could not have said it better, this is your best method to save time and memory. Typically our old process would be to use a hard number at 0.01" inch for a tolerance. This caused some large run times with STL files reaching 100mb+ and RAM usage up to 12GB. Your described method above is the best option for an all-round process.

I have heard before that "cut tolerance" is a volumetric tolerance based on your STL file. This is something that always through me for a curve ![]() , that is another story however.

, that is another story however.

Offline

#10 2012-04-30 15:15:38

- MustaphaC

- VERICUT Specialist

- From: Le Mans, France

- Registered: 2004-10-14

- Posts: 130

- Website

Re: Cut Stock Tolerance.

Hi JaydenR,

You are not totally wrong. This is not exactly a volumetric tolerance based on Stock size, but kind of ![]() . If we "try" to give it a definition, we would more say that this value defines the smallest value in a direction which VERICUT can detect. So for example if you have a value of 0.5 (mm project) Cutting Tolerance based on Stock size that means that a rapid motion removing a volume 0.5x0.1x0.1 will be detected. So for a Cutting Tolerance of 0,5 you detect a volume of 0.005mm3!

. If we "try" to give it a definition, we would more say that this value defines the smallest value in a direction which VERICUT can detect. So for example if you have a value of 0.5 (mm project) Cutting Tolerance based on Stock size that means that a rapid motion removing a volume 0.5x0.1x0.1 will be detected. So for a Cutting Tolerance of 0,5 you detect a volume of 0.005mm3!

You can make a test in a mm project with any Stock for example 1000x1000x1000, create a tool of 0.5 diameter, cutting tol. 0,5 on stock size and rapid motion plunge of Z-0.001, you will see rapid error detected and an error such as this will be reported:

Fast feed rate removed material with tool "1" loaded in component "Tool" at line: (2) G0Z-0.001. Removed volume 0.000088

That is pretty accurate, no ![]() ?

?

Mustapha

Offline

#11 2012-05-01 00:10:16

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

Re: Cut Stock Tolerance.

Hi all!

Thank you very much for this knowledgeable set of answers... that was far more clear!

Tks

Daniel

Daniel Santos

Offline

#12 2012-07-08 15:15:26

- ecapatto

- Member

- Registered: 2010-05-27

- Posts: 11

Re: Cut Stock Tolerance.

Hello everybody,

This is our problem at GE, huge parts (to be honest sometimes really bigger than Daniel said) with very small and precise details, a lot of them, everywhere around these parts. So the ability to see small gouges is imperative.

This topic helps me to understand better how the VC tolerance system works, and you're right, if you (we) need to see something we need to look at it, I guess that it should be the best way.

Thank you by the advance,

E.Capatto

NC Programer - CAV Support - Software Developer

GE Oil and Gas Brazil

Offline

Pages: 1