VERICUT Users' Forum

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2012-05-01 00:51:40

- Verifun

- Senior Member

- From: U.S.

- Registered: 2005-03-31

- Posts: 351

- Website

ProeV

Ok,

I'm using 7.1.6 and went through the what's new in this interim release...

*** Request #1:

ProeV needs the ability to select toolpath files with extensions other than .tap or .ncl - We're forced to rename all our NC-Programs to use it... and we can't simple go to the programs folder on the network drive which contains the nc-programs that are sent to the machines... so we have to copy this program somewhere, rename its extension, validate in Vericut and then open it and paste its contents inside the original nc-program... yes, it's boring like reading this entire sentence...

*** Request #2: Add support for TOOL_POINT CSYS to compute the gage offset for turning tools.

7.1.6 can read parameters to compute the gage offset for angle heads... but nothing for the most common situation: Ordinary turning tools.

From the release notes:

"The Pro/E-to-VERICUT Interface (PROEV) is enhanced to enable using Pro/E

parameters to specify the Gage Point in Tool Manager. The tool's gage point and

orientation will be calculated as follows:

If a "TIP" csys and a "SPINDLE_CONTROL_POINT" csys are defined, then their

values will be used to compute the gage point and orientation.

If a "TIP" csys and a "TOOL_ATTACH_POINT" csys are defined, then their values

will be used to compute the gage point and orientation.

If "GAUGE_X_LENGTH" or "GAUGE_Y_LENGTH" or "GAUGE_Z_LENGTH"

are defined, then the respective value will be used as X/Y/Z coordinate for the gage

point.

If "LENGTH" is defined, then its value will be used as the Z gage point."

Nice to have:

The most common CSYS inside a tool model is TOOL_POINT because this CSYS represents the gage point of the tool for machine simulation purposes within Pro/NC.

SPINDLE_CONTROL_POINT and TOOL_ATTACH_POINT are only used with angle heads (Attachments)

So what we'd like to see is ProeV to look for a CSYS named TOOL_POINT, and if one is available within the tool model, the GAGE distance in the tool manager is computed as the distance from TOOL_POINT to TIP - That would solve a often problem with ordinary turning tools which are far more common than angle heads.

If GAUGE_X_LENGTH" or "GAUGE_Y_LENGTH" or "GAUGE_Z_LENGTH" are available, the are usually measured from TOOL_POINT CSYS too, because this CSYS is the GAGE point of ANY tool for machine simulation purposes within Pro/NC.

If the machine simulation mechanism also has a component with a CSYS named TOOL_POINT inside it, Pro/NC will couple the TOOL_POINT CSYS from the tool with the TOOL_POINT CSYS from the machine component and use this in the simulation.

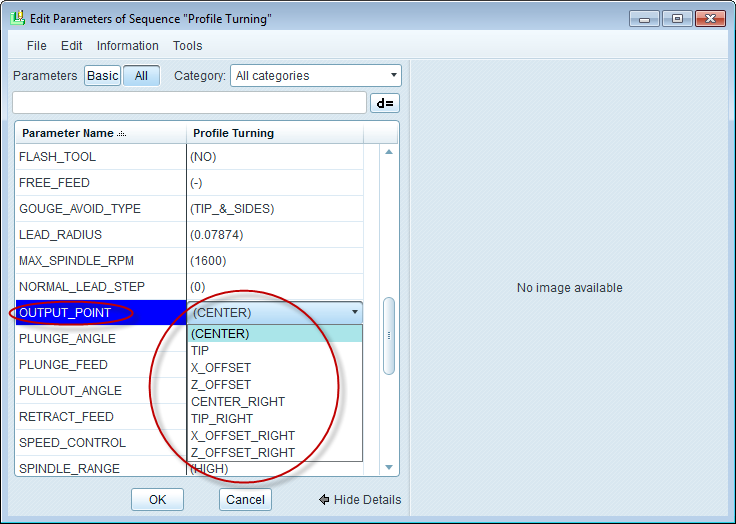

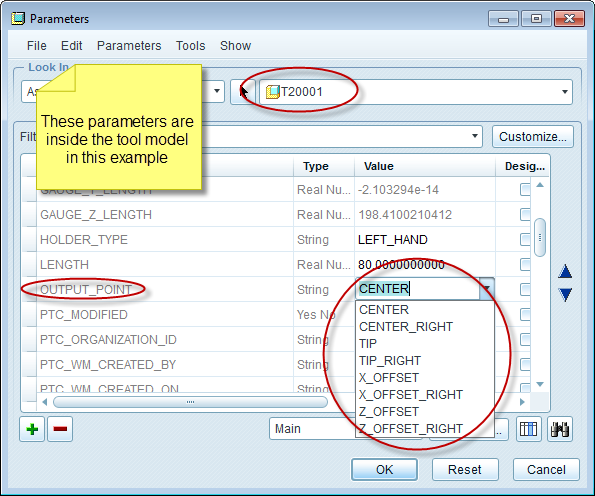

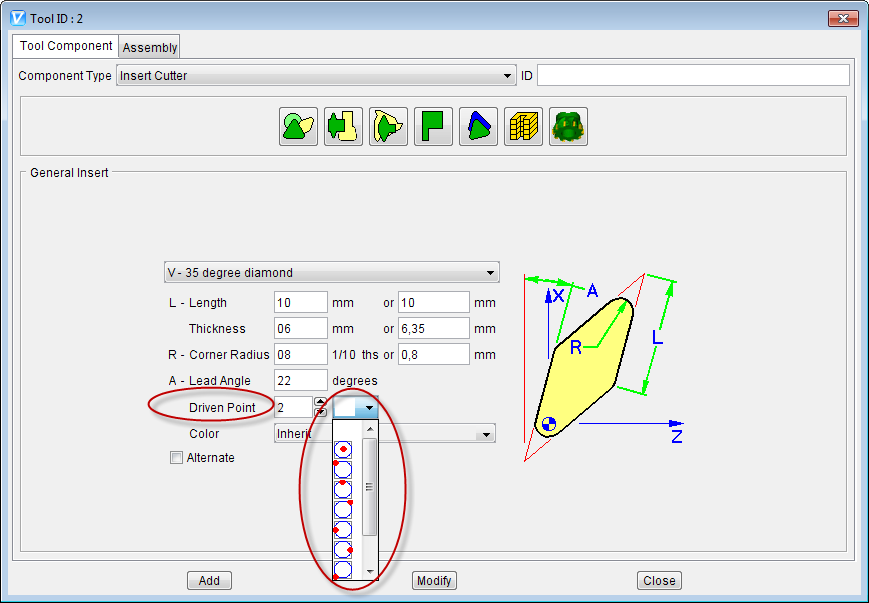

*** Request #3: If the tool model contains the parameter OUTPUT_POINT, define the driven points of a turning tool using this value

Hope we can make these possible...

Tks

Daniel

Daniel Santos

Offline

Pages: 1