VERICUT Users' Forum

You are not logged in.

- Topics: Active | Unanswered

Pages: 1

#1 2010-05-05 06:36:44

- DavidB

- Member

- From: Australia

- Registered: 2005-02-09

- Posts: 27

V7.0.3 Sin810d

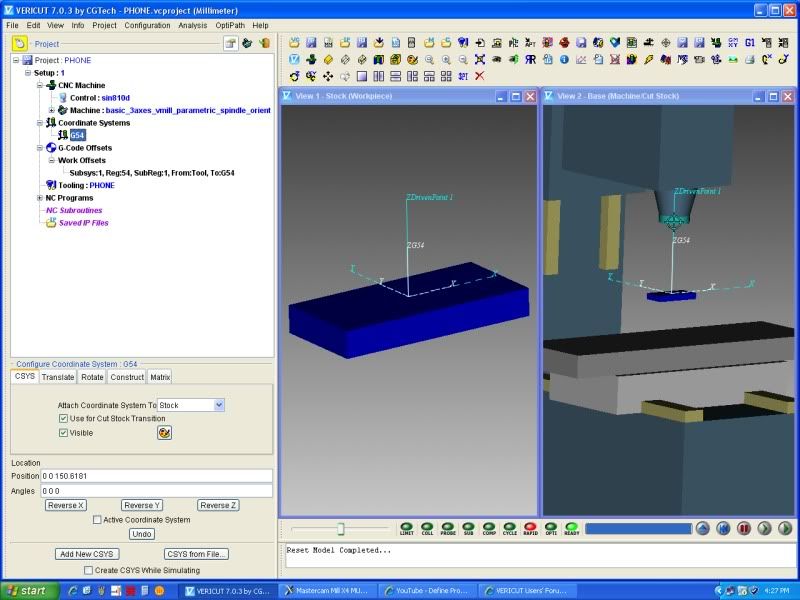

I'm using the Sim810d control and the I cant get the Tool tip to my G54.

The spindle nose goes to G54, even in MDI T1 M6 Z0. the spindle nose goes to my G54 Z0.

What am I doing wrong?

Thanks in advance Dave

Offline

#2 2010-05-05 11:17:15

- MIKEFITZ

- Member

- From: Chicopee, MA

- Registered: 2009-06-18

- Posts: 104

Re: V7.0.3 Sin810d

How do you have your programming method set? Click on Setup, then G-Code... also, do you have a code in your program to call the tool length offset? it seems as though your machine is behaving like there's no tool in the spindle, which is probably just some small detail. god knows i've had plenty of those causing me issues! haha...

Mike

Hoppe Tool

Offline

#3 2010-05-07 01:12:51

- DavidB

- Member

- From: Australia

- Registered: 2005-02-09

- Posts: 27

Re: V7.0.3 Sin810d

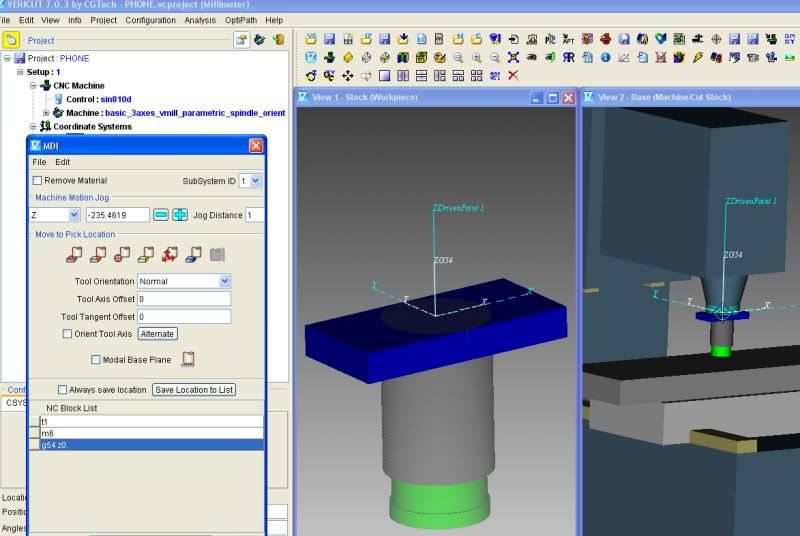

Yes the machine in Vericut is acting like there is no tool length. It puts the spindle nose to the G54.

But the actual machine works fine on the shop floor.

There is no G43 call on Siemens once a tool is called it auotomatically uses the tool length just like a Heidenhain controller.

Sample of code:

N1 G00 G17 G71 G40 G90

N2 ;FACE

N3 T1 ;63MM FACE MILL

N4 G17

N5 M6

N6 G641 ADIS=0.001

N7 ;MAX - Z11.

N8 ;MIN - Z.3

N9 G00 G90 G54 S600 M03

N10 X-75.25 Y-13.289

N11 Z11. T2

N12 X-75.25 Y-13.289 Z4.

N13 G94 G01 X-75.25 Y-13.289 Z2. F500.Offline

#4 2010-05-07 11:14:07

- MIKEFITZ

- Member

- From: Chicopee, MA

- Registered: 2009-06-18

- Posts: 104

Re: V7.0.3 Sin810d

It sounds like you would have to add a command to the tool change, probably "ToolLengthCompPos", so that the machine in Vericut knows to apply the TLO as soon as the tool is in the spindle. I have something similar set up myself, for my cutter dia. comp, and it seems to work pretty well. I would say add it in your control under Registers, T, (and M6), ToolLengthCompPos. This is just a guess, but I think it should work...good luck!

Mike

Hoppe Tool

Offline

Pages: 1